“WHAT IS A THERMOTRANSFER (HEAT TRANSFER MATERIAL)?”

To answer to this question, we first must know that: thermotransfer materials, are plastic materials.

Plastic materials are divided into 3 main categories:

- Thermoplastic Polymers:

- These are materials which can be softened and reshaped when exposed to the right temperature and pressure. Once the action of heat and pressure stops, they regain their rigid form. This characteristic is called “plastic memory”.

- The best-known thermoplastic polymers are: PE (polyester) – flexible, light and very resistant; PP (polypropylene); PVC (polyvinylchloride) – one of the most consumed plastic materials in the world

- Thermohardening Polymers:

- These are plastic materials, which given the correct pressure, heat conditions, and/or in the presence of certain substances, become rigid. Ironically, at a certain stage, when the heat and pressure are balanced, these materials soften like thermoplastics, allowing us to work with them inside that window of equilibrium.

- The best known and most used thermohardening polymer is, polyurethane (PU).

- Elastomers:

- These are rubbery polymers, characterized by high elasticity and its ability to reshape.

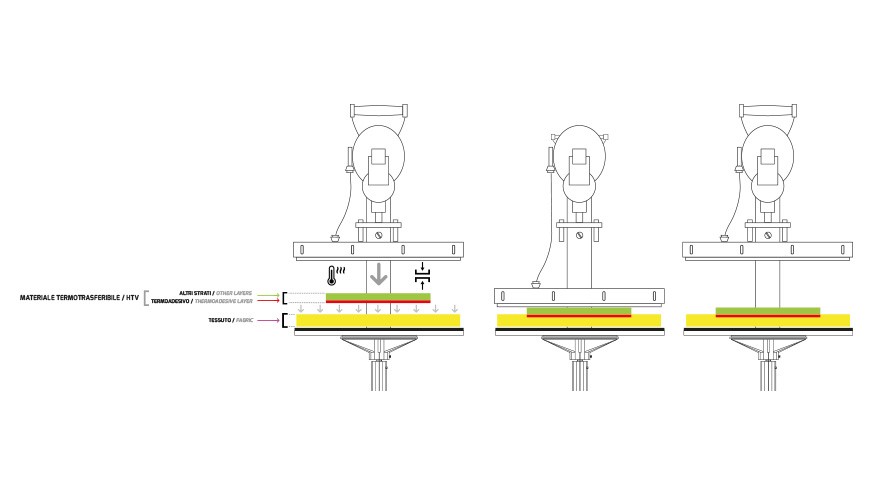

Let’s go back to the beginning: thermotransfer materials are made of multiple thermoplastic or thermohardening polymers, which are layered one over the other. These materials can deform elastically under heating and pressure.

So how do thermotransfer materials adhere to the fabric?

One of the polymers, which is called thermoadhesive, allows the binding to the fabric.

The most common thermoadhesive polymers are:

- co-polyesters

- co-polyamides

- polyurethane

The prefix “co” in this case, indicates that certain additives are added to the polymer, which creates a material capable of binding to different types of fabrics, as long as they are not treated in any particular way.

The mechanism by which the thermoadhesive polymer can bind to the fabric fibers, is linked to the properties we covered above.

Once the correct temperature and pressure is applied to the thermotransfer over the fabric, the thermoadhesive permanently binds to the fibers of the fabric, without altering its original composition.

In the next article, we will talk more in depth on the layering process of the thermotransfer materials.