If you’ve been wondering “Why isn’t my htv sticking?”, you’ve landed in the right place.

These are some of the most common reasons why your htv is not sticking to fabric.

1. What fabric are you applying the vinyl to?

Check the tag on your shirt. Find out what the item you’re applying to is made of. Some HTV isn’t compatible with certain fabrics like nylon or sublimated polyester.

2. Are there thick seams, buttons, zippers, or collars?

All of these things can be the root of the problem. When applying on irregular surface, we recommend using SISER® heat transfer pillow. It will lift up the part of the garment that is not getting enough pressure, giving your design a smooth, even surface. Watch the tutorial and learn how to use SISER® pillows (CLICK HERE)

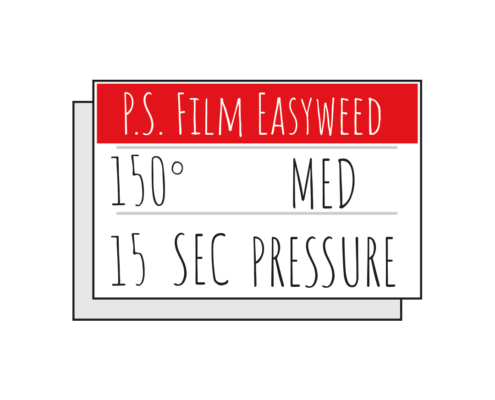

3. Did you follow the right “application instructions”?

Each HTV has its own “application instructions”. Time, temperature, and pressure* are all extremely important factors. Make sure to follow the right instructions when applying SISER® HTV. Download or print our Quick Guide for easy reference (CLICK HERE)

*Pressure –> This is usually an issue you’ll run into with using a home iron rather than a heat press. It’s tough to press iron firmly on your design, especially if it’s a large design. Good pressure is when your arms literally shake from pushing down so hard. You also have to consider the surface on which you place the fabric. Beware of surfaces that will absorb the heat from the iron. Do not use the ironing board or anything that will prevent you from pressing the iron firmly.

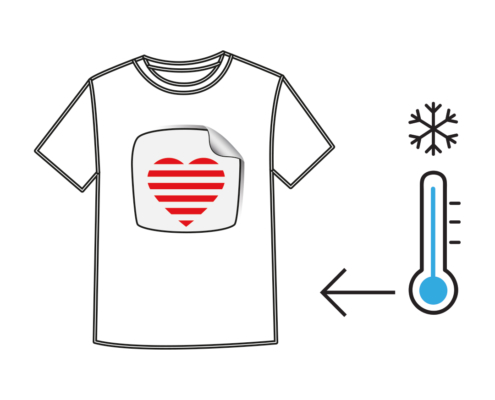

4. Peel hot or cold?

Some types of HTV need the carrier to be peeled hot, right after the application. Others need to cool off completely. Peeling incorrectly can definitely ruin your design. Don’t take this risk, download or print SISER® HTV Reference Chart (CLICK HERE)